Process

Murandi has designed and implemented a highly effective, single iteration, product design process where risks are managed through a documented review process and product delivery is realized in a five phase design process.

In the System Design phase, Murandi starts by first determining and documenting our clients\' requirements

and subsequently translating them into detailed technical specifications.

The technical specifications lead to a specialized acceptance test plan defining the standard for verification for each specification.

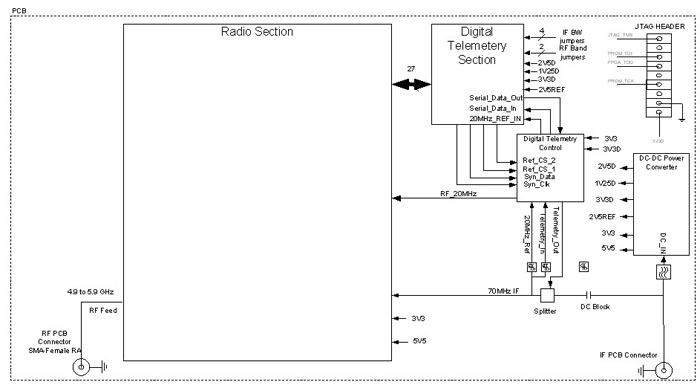

The product is then broken down into modules and a high level analysis done from top to bottom. The full complement of system design documention is extensive and serves to ensure that Murandi and their client are working from a common understanding of:

- What the product needs to do and what it will cost to build

- How the design is partitioned and how the partitions interact

- How and where the product is going to be manufactured

- The level and impact of all significant risks

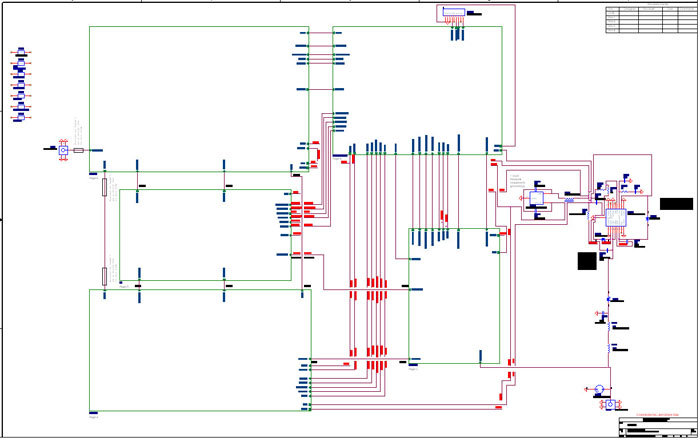

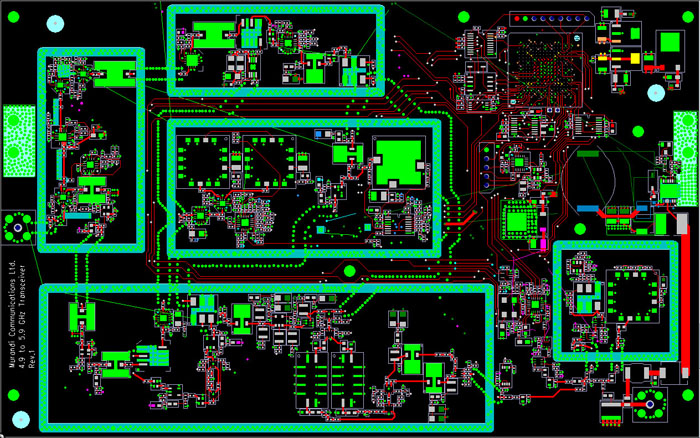

In the Detailed Design phase, things such as schematics, layouts, assembly drawings, detailed BOMs, as well as code are created. Simulations or appropriate analysis is completed, as required, for every part of the design.

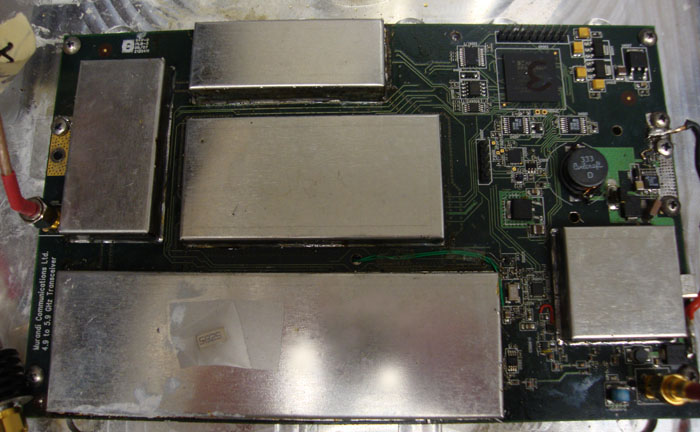

In the Prototyping phase, the product is built and the design verified through a comprehensive development test plan which culminates in a formal test plan guided by the Acceptance Test Plan.

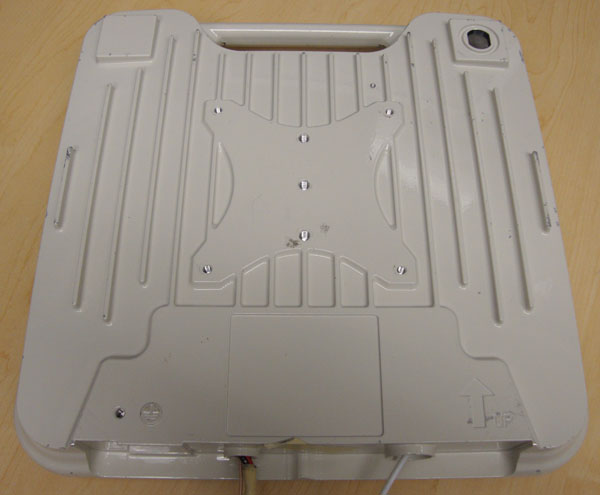

The Validation phase includes higher level integration, pre-pilot builds, formal regulatory testing, and field trials as appropriate.

Finally the Manufacturing phase focuses on successfully integrating the product into the designated manufacturing facility.

A formal review process governs each phase of the program - efficiently guiding the design to ensure that it stays on track and that communication is open and effective.

|

|